Safety shoes and occupational footwear

Ensure that the footwear is adapted to your daily work and tasks

The primary function of safety shoes is to protect the feet. Protective shoes must also have an anti-glide sole, be water-proof and very durable in order to protect the feet over a long time. Our protective shoes must give the users a safe workday, and it is also very important to us that our protective shoes are a good fit and feel comfortable on during eight to ten hours every day, with temperatures of around 28 to 32 degrees Celsius.

Our newest models

Safety shoe collection!

The Panacea - safety footwear series has been created to meet your requirements for both safety and comfort. We have combined advanced technology and first-class materials to give you safety shoes with a tough and modern look, perfect for both work and leisure.

The collection consists of low shoes, ankle boots and boots made from full grain LWG certified leather. The leather not only looks good and is durable, but it is also produced in an environmentally friendly way.

From the Panacea range, you can choose between quick-lock models for ease of use or lacing for extra adjustability. The Panacea boot has both lacing and a side zipper, so you can adjust the fit to your foot and ancle. The series even includes a "pull-on" boot.

The boot named Challenger WP also has a waterproof membrane that keeps your feet dry, even in the most challenging weather conditions.

The Vibram outsole is designed to give you maximum grip so you can feel confident wherever you go and with the fiberglass toe cap you can be sure your feet are protected from falling objects and pinching. In addition, there is a soft spike tread sole in the shoe series that gives you a secure sole against penetration while not preventing your foot from easily rolling over the ground when you walk.

For increased comfort, Panacea safety shoes have a 3D mesh lining that provides good moisture absorption, so that your feet feel dry and fresh all day.

In the Panacea series, you get certification according to the latest standard EN ISO 20345-2022.

All Wenaas-produced footwear now features Leather Working Group® leather

Choose leather shoes with a clear conscience

Leather Working Group (LWG) sets the standard for environmentally friendly leather production.

All our Wenaas-produced leather shoes are now made with leather from LWG®-certified tanneries – an important step toward a more sustainable future without compromising on quality, comfort, or durability.

When you choose Wenaas leather safety shoes, you’re not only choosing durability and comfort but also an eco-friendly solution. Explore our shoes with LWG® leather and experience how quality and sustainability go hand in hand.

Berserk's history goes back to 1887, when it was founded as Kristiandsunds Oljekledefabrikk, while it was taken over by Wenaas in 1997. We are now re-establishing the trademark Berserk. Our shoe collection is called Berserk.

We have spared no expense on our protective footwear collection "Berserk". The collection contains products with new technology and material of the highest quality.

Berserk - safety footwear for rough use, for sectors such as oil and gas, heavy industry and building and construction.

The models in Berserk are extremely flexible and energy-saving when walking, something you notice when you have worn the safety shoes for an entire workday.

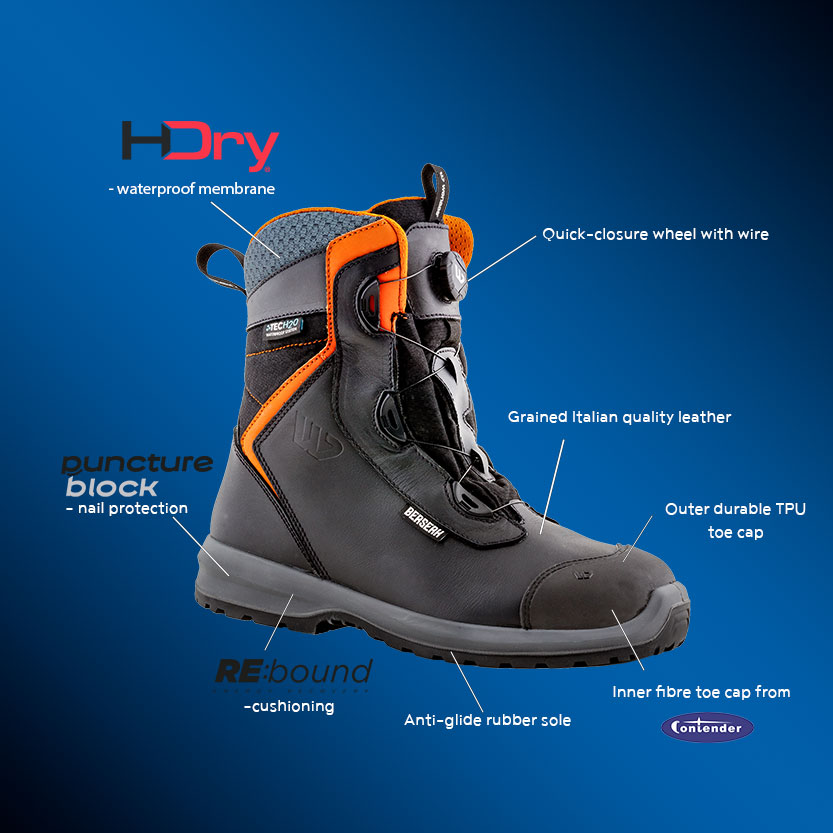

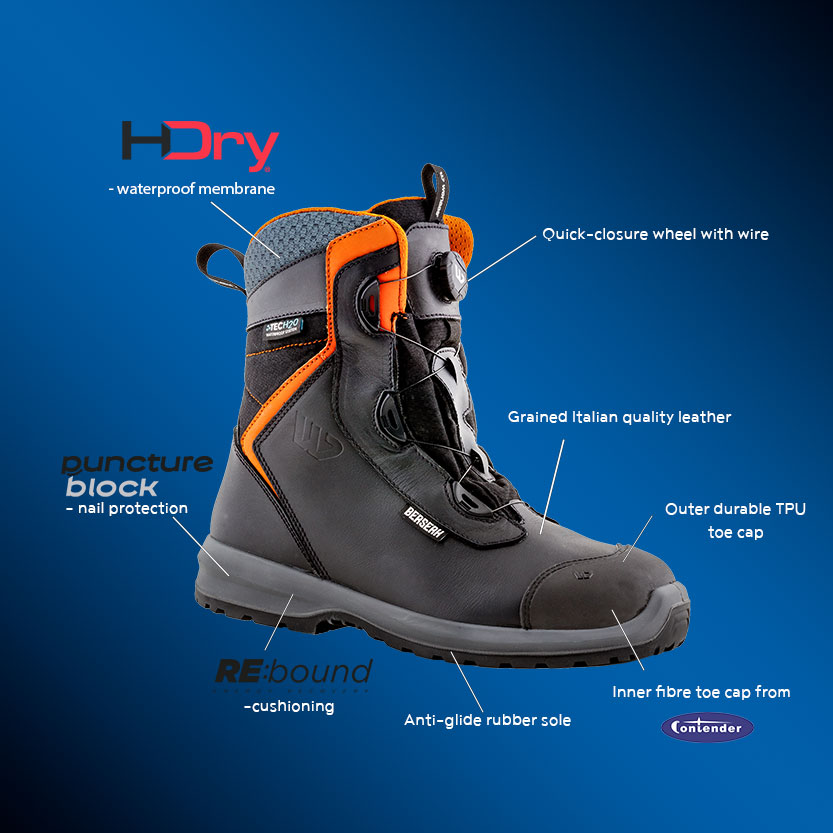

Below, you can also read about the great quality materials and new technology we have developed for this collection.

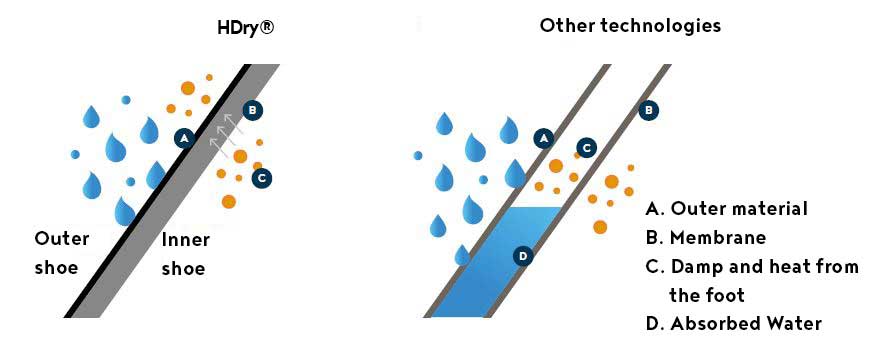

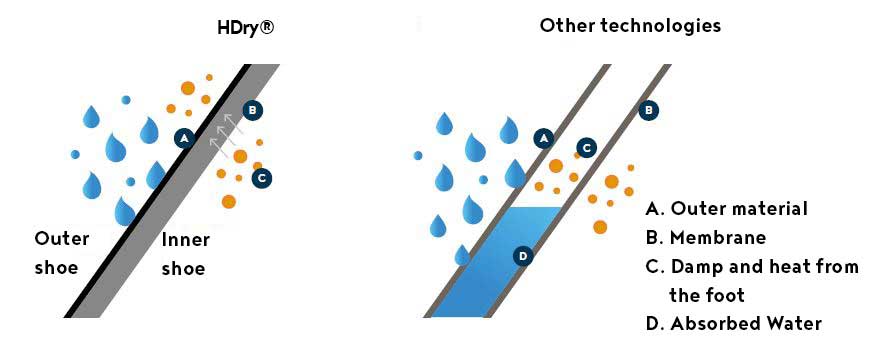

Left Illustration of Berserk's sock inside the shoe. Right Illustration of how other technologies for water-proof systems have several layers where where damp can accumulate and lead to a feeling of clammy feet.

HDry® waterproof membrane is our water proof system used in our Berserk collection. Our membrane works as a sock directly laminated on the leather.

There are no seams in the sock that create small holes in the membrane and therefore leakage. This way of attaching the sock ensures that no bumps or creases are created on the membrane. It also ensures that damp is not accumulated between the lining and outer material, which can is often the case with other technologies. DRY FEET DURING THE ENTIRE WORKDAY!

Our demonstration shows how HDry® keeps the damp outside, while damp and heat is released from the shoes, in comparison to other protective shoes in which absorbed moisture remains accumulated between the outer leather and inner material.

HDry® membran

HDry® video shows how the membrane sock is mounted to the upper.

ReBound provides a unique balance between energy absorption (cushioning) and energy return in the shoe's sole. During the development of the Berserk collection, we have focused greatly on comfort. Protective footwear is probably the footwear you'll end up using the longest during the course of a day and should therefore be of the highest quality to protect your feet and prevent knee and back issues.

We have used a material known as ReBound on the heel counter of the shoes comprising the Berserk collection. In laboratory tests conducted by Ricotest on behalf Din 53512, Rebound's score was at a par with famous brands known for their comfortable soles. We have done everything we could to ensure that this collection becomes your favourite while at work.

Our Puncture Block midsole is soft and flexible. This means that your foot spends less energy on walking. This sole has no hard surfaces between the PU outer sole and the insole. Nevertheless, your foot remains protected against nails and sharp objects that can perforate the outer sole.

The sole is sustainable and made from environmentally friendly material.

Work Comfort EVO insole

Work Comfort EVO sole

Work Comfort EVO sole ensures that the air circulates inside the shoe. The insole has highly absorbent and breathable properties, which make your feet feel dry and fresh.

The foam sole has cushioning and a memory system to ensure longer durability.

Contender glass fibre toe cap

The toe cap is made from a robust glass fibre and is 50% lighter than traditional toe caps, resistant against corrosion and electrical isolation, with excellent heat isolation and cold isolation. The compression tests comprise all global national safety standards. The thickness is also the thinnest in the market, at the same time as adhering to safety and all standards.

The entire Berserk collection has been approved in accordance with the American ASTM standard.

We have re-establised the brand Verner. Verner was originally founded as Møre shoe factory in 1918 and was taken over by Wenaas in 2002.

The collection consists of products for use in the service industry, work in warehouses, the craft industry and the marine industry with a focus on lightweight shoes and high-quality materials. In the U.S. we offer the Decksure safety shoe for our customers.

Verner Decksure shoe - this shoe puts the sole centre stage!

Our sporty safety shoe Verner Decksure has a specially developed PU sole, which is particularly well suited for slippery floors. The outer sole has a big contact surface and good grip on wet and smooth floors.

The sole performed very well on the slip safety test on the new EN 20345 standard.

Extensive development and tests of protective shoes – the search for the ultimate model

At Wenaas, we are well acquianted with the standards concerning protective footwear. We interpret and develop protective footwear that surpass the minimum requirements. The users provide us with important feedback and insight into real requirements, wishes and experiences through the different HSE-committees we participate in. We do not find it sufficient to follow the standards for protective footwear; we surpass the requirements when it comes to support and slip protection. This means that we produce protective footwear adapted to Nordic feet. We also use lightweight toe caps that provide excellent protection, at the same time as leaving room to move the toes freely. We have literally tailored protective footwear for workers in highly different sectors with different specific requirements.

We have a large selection of shoes and safety footwear, and we will always find or develop a solution that suits all our customers. We know what it's like to walk a mile in your (protective) shoes.

Protective shoes and work shoes for all sectors

There is often some confusion between the terms anti-static, ESD and electric isolation when it comes to footwear. Both anti-static and ESD footwear prevent/reduce static electrical charge to the body. This reduces electrical flashover (shock/charge/spark), and/or protects electrical equipment (ESD) by sending electrical charge to the ground. This is very different from electrically isolated footwear (EH tested), which protects against charging high-voltage electricity to the ground, which can be extremely dangerous.

Wenaas is familiar with the rules for protective footwear in detail and makes products that exceed the minimum requirements. In cooperation with the users, we tailor our footwear and protective shoes with stringent safety demands to workers in different sectors, such as oil and gas, transport, building and construction, etc.

Antistatic

Antistatic approved footwear redirect static electricity that has been accumulated in the body by redirecting it back to the ground, but with a relatively low conductivity. They are also electrically isolated against electrical shocks from machine up to 230 volt. The values for the resistance is 100 KΩ - 1000 MΩ, which is far above the standards for ESD-approved footwear. Risk of ignition, for instance of combustibles, is reduced. Anti-static footwear is a good alternative in places with a low risk of explosion and in places where static electricity is unworkable, and also for general use.

ESD protective shoes

ESD-approved shoes, approved in accordance with IEC 61340, redirect the static electricity that gathers in the body by gathering it to the ground in a safe and controlled way. The values of the resistance is lower than 100 MΩ. It means that ESD footwear does not isolate, and does not protect against electrical shocks, and should not be used if there is a risk of shock from electrical machines. ESD shoes–ideally combined with ESD clothing–is suitable for work with electronic equipment, and ensures that you can prevent damage on the equipment. ESD footwear is the best alternative for those working in areas with a risk of explosion (ATEX zones) and general use.

Electrical isolation

Electrically isolated footwear do not conduct electricity, and approved is accordance with ASTM F2413-18 EH up to 18,000 volt. In the event of an accident, the footwear will isolate against the ground, so that the electricity does not go through the body and back to the ground. Electrically isolated footwear is the opposite of ESD and antistatic footwear, and is therefore not not suitable for environments with a risk of static electricity that can ignite combustible and liquids or work with fragile electrical components. The shoes are suitable for use in voltage environments.

The stability of the work shoe

Find out why you should wear work shoes to work and not regular sneakers.

Watch the film on the left.

Maintenance and cleaning of protective footwear extend the durability of your shoes

Dirt and humidity has little effect on shoes that have been maintained properly. Suitable maintenance is important to keep the shoes comfortable and extend the durability of the shoes. Protective footwear should be maintained clean, dry and looked after over time.

The shoe upper can be easily cleaned with a shoe brush, or with a damp cloth. Protective shoes that are very dirty must be washed in luke-warm mild soapy water, and rinsed.

Never dry protective shoes near heat sources, such as ovens or heating cabinets. The leather dries out, turns hard and can crack. We recommend to open the tongue and remove the insole for optimal drying.

Protective shoes in leather must be treated with shoe cream, and ideally with impregnation spray.

Protective shoes in textile must be treated with impregnation spray. Do not use products that include fat or oils, as it reduces the breathable properties to the materials in protective shoes. In the event of reduced breathability, the feet can become clammy, thus reducing the level of comfort.