Respiratory protection equipment

Airborne pollution in the form of gas, vapour or hazardous particles can damage the lungs and other vital organs and cause the person exposed to develop asthma or allergies.

Respiratory protective equipment protects against various types of air pollution.

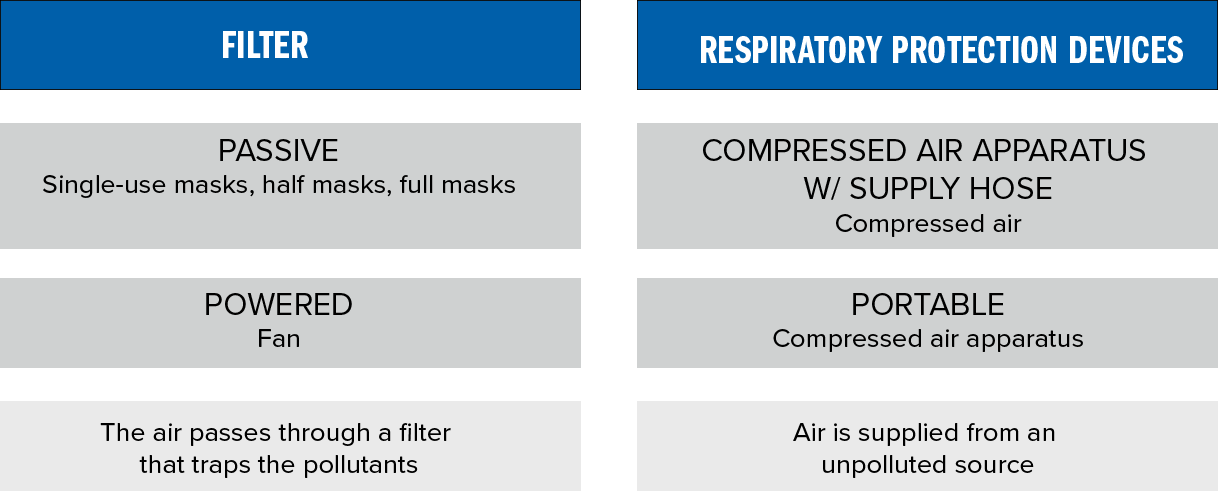

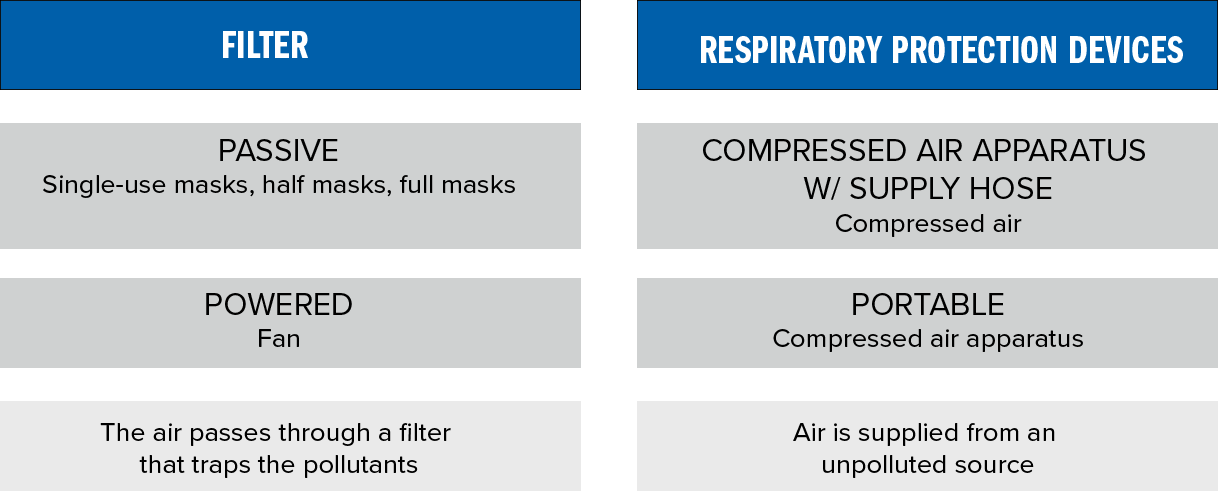

Respiratory protective equipment can be divided into two categories and in order to know which type to choose, you need to know the type of pollution you wish to protect against.

Filtered respiratory protection devices

In order for filtered respiratory protection devices to be used, the air needs to contain at least 19.5% oxygen. The filter type is chosen based on the type of pollution you wish to protect against and should be used in accordance with the manufacturers’ filter guides.

Breathing apparatus

If the air contains less than 19.5% oxygen, a breathing apparatus supplying air from a non-contaminated source must be used. This also applies where odourless gases are present.

Choosing a respiratory protection device:

- Identification: What harmful gases, dust, smoke or aerosols do you need to protect against? The workplace must undergo an assessment to establish pollutant concentrations.

- Risk assessment: Is there sufficient oxygen throughout the entire exposure period? What health effects are associated with the various risk zones? Are there other risks such as sparks or explosive compounds?

- Choosing a respiratory protection device: Half face mask, full mask, fan-assisted or compressed air. In situations with a low workload: Half or full mask with filter. In situations with a higher workload or longer shifts: Fan-assisted filter protection. In situations where oxygen levels are low and in the presence of odour and flavourless gases: Compressed air apparatus. Choose the right filter based on the supplier’s recommendations.

- Training: Fitting, function control, assembly, storage and maintenance. Routines for cleaning and replacing filters and consumable parts.

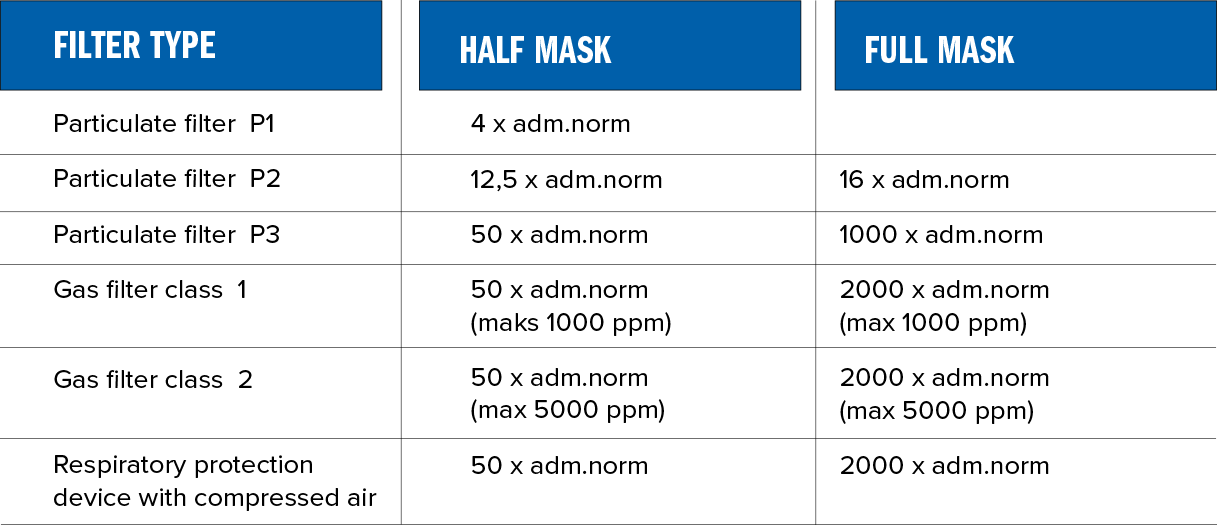

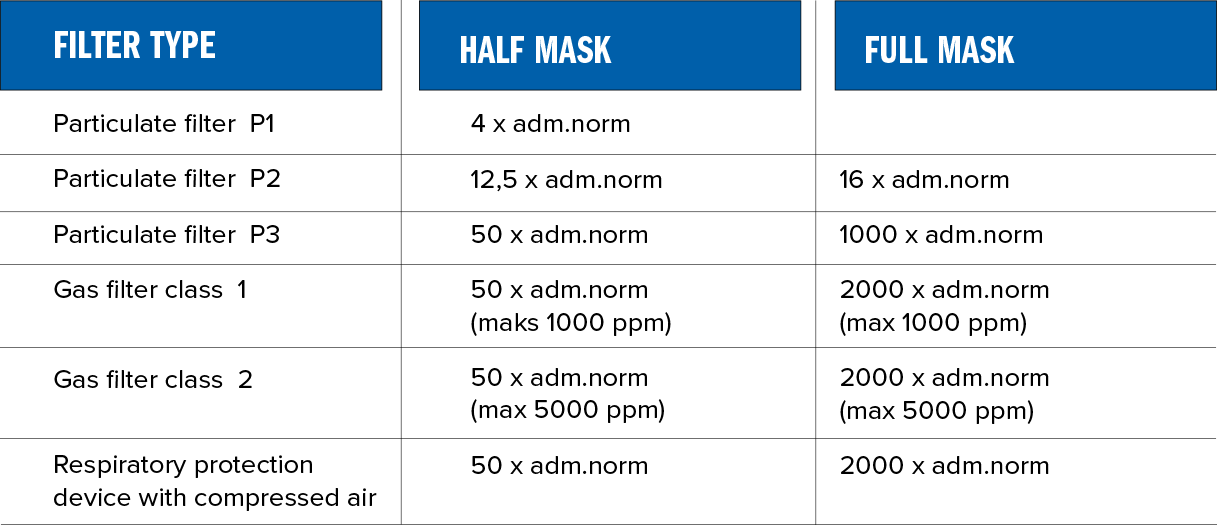

Protection factor for filtered respiratory protection devices in accordance with European norm (NPF):

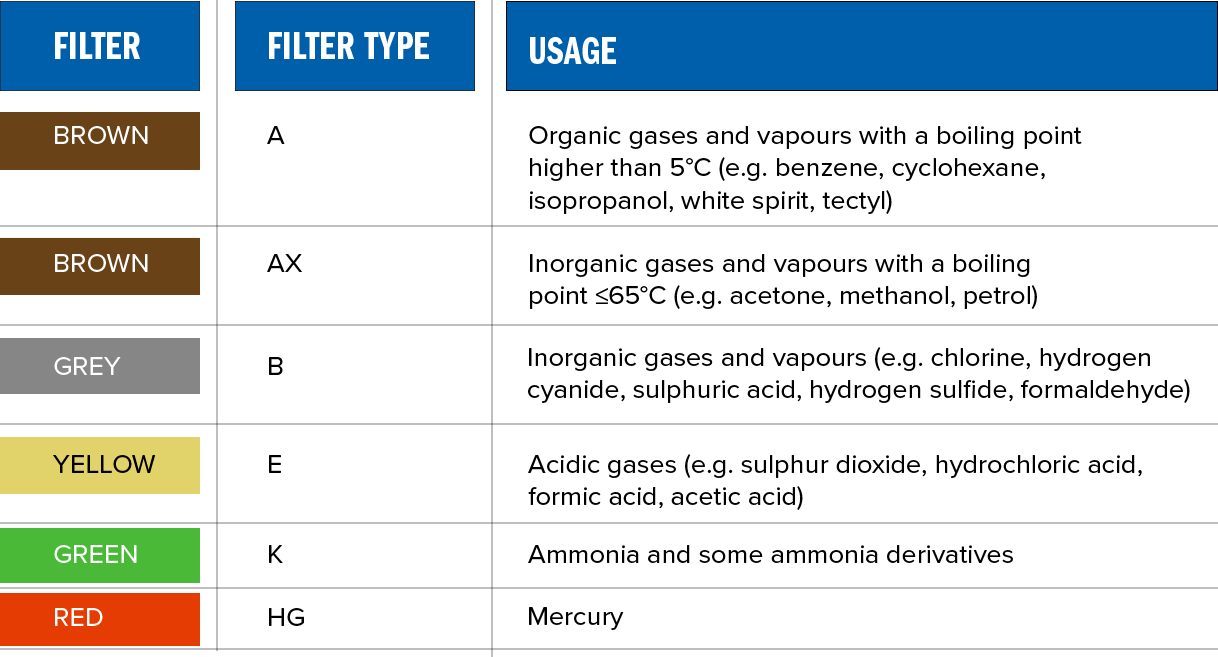

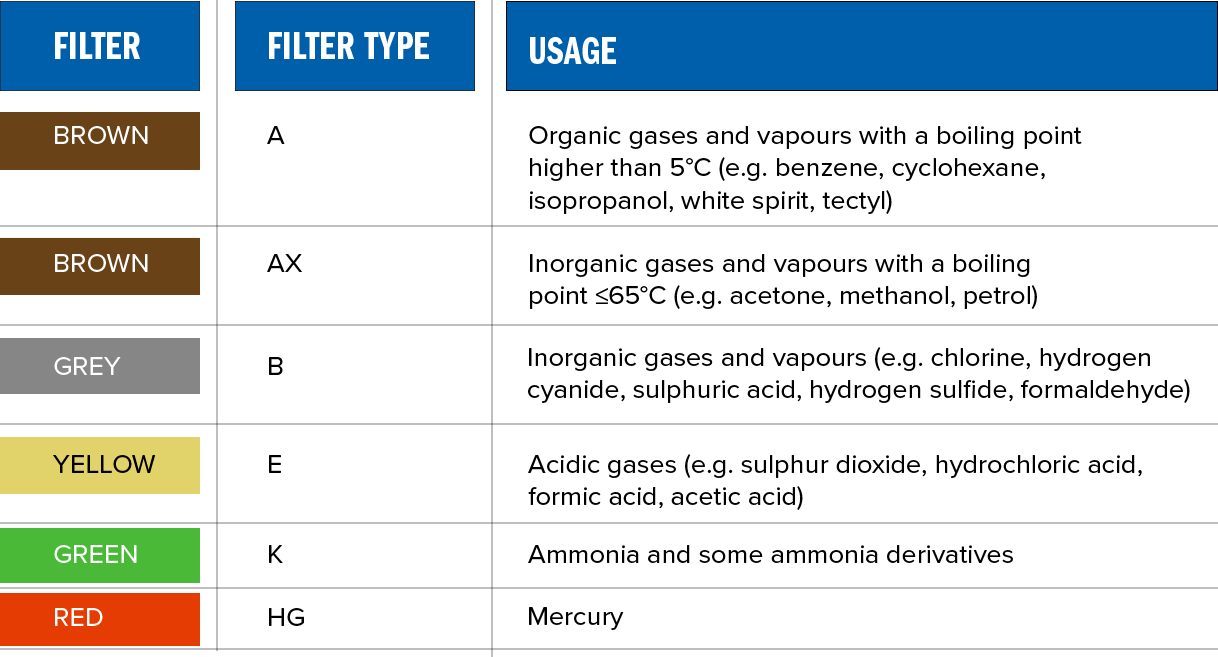

Gas filters in respiratory protection devices:

Protection against gases/vapours using a carbon filter. There are often a variety of gases/vapours present in one location. The gases/vapours must be known in order to be able to select the right gas filter (see the manufacturers’ recommendations). A combination filter should be used where a combination of gases/vapours and particles is present.

Examples of uses for respiratory protection devices:

- A: Solvents used in connection with paint, varnish and glue work. Pesticide spraying. Disinfection of greenhouses and chicken coops.

- B: Electrolysis work (acidic gases) Chlorination plants in water works (chlorine) Emptying of liquid fertiliser plants (requires oxygen level of at least 19.5%)

- E: Ore roasting. Combustion plants (sulphur dioxide).

- K: Paper and chemicals industries (ammonia).

Protection Factor:

The protection factor illustrates how effective the device is at reducing the levels of pollutants that enter the airways, i.e. the mask.

Assigned Protection Factor (APF): Based on measurements taken outside and inside the respiratory protection device, conducted in, amongst other places, real work environments and on working personnel. The APF is significantly lower than the theoretical protection factor.

Nominal Protection Factor (NPF): Based on laboratory measurements made in connection with approval of the respiratory protection device’s EN standard. Concept based on theoretical leakage percentage (e.g.: FFP3 mask with a max. leakage of 2% gives a protection factor of 100/2 = 50).

Hygiene Limit Value (HLV): Value set by the authorities (administrative norm) stating the maximum permissible average concentration throughout a workday as well as the maximum limit value. Administrative norms are published by the Norwegian Labour Inspection Authority.

Calculating recommended protection factor (RPF): Pollutant concentration/HLV (e.g. concentration 1,000 mg/m3 and a hygiene limit value of 100 mg/m3 gives a recommended protection factor of 10, i.e. a respiratory protection device with protection factor 10).

Products

Related articles

Eye protection

Eye protection and safety goggles of different types are a necessity for many professional groups.

Fall protection

Working at heights is the riskiest form of work one can do.

Work light

Wenaas has now expanded the range with Nightstick lamps and work lights