Work Gloves

It can be challenging to choose the right work glove, especially considering different tasks and approval requirements. There is a wide range of gloves with various features and certifications, and it’s not always easy to know which one is the best fit.

We can help you get a better overview, so you can make a safe and informed choice when purchasing gloves.

Read more about Disposable Gloves >>

EN standards - protective gloves

The standards include requirements and test methods for how the products must be tested and labeled.

EN ISO 21420:2020: General requirements and test methods

EN 388:2016 + A1:2018: Mechanical risks

EN 374:2016: Hazardous chemicals and microorganisms

EN 12477:2001 + A1:2005: Welding

EN 407:2020: Hand protection equipment against thermal hazards

EN 511:2006: Cold (down to -50 °C)

EN 455: Medical use

ASTM F2675/F2675M – 19: Protection against electric arc

ANSI/ISEA 138-2019: Impact

EN 388 versus ANSI/ISEA? What is the difference?

When choosing protective gloves, it is crucial to understand the various standards that apply to ensure the best possible protection against injuries. Two of the most recognized standards are the European EN 388 standard and the American ANSI/ISEA 105 standard. These standards have different approaches and methods. Let us enlighten you.

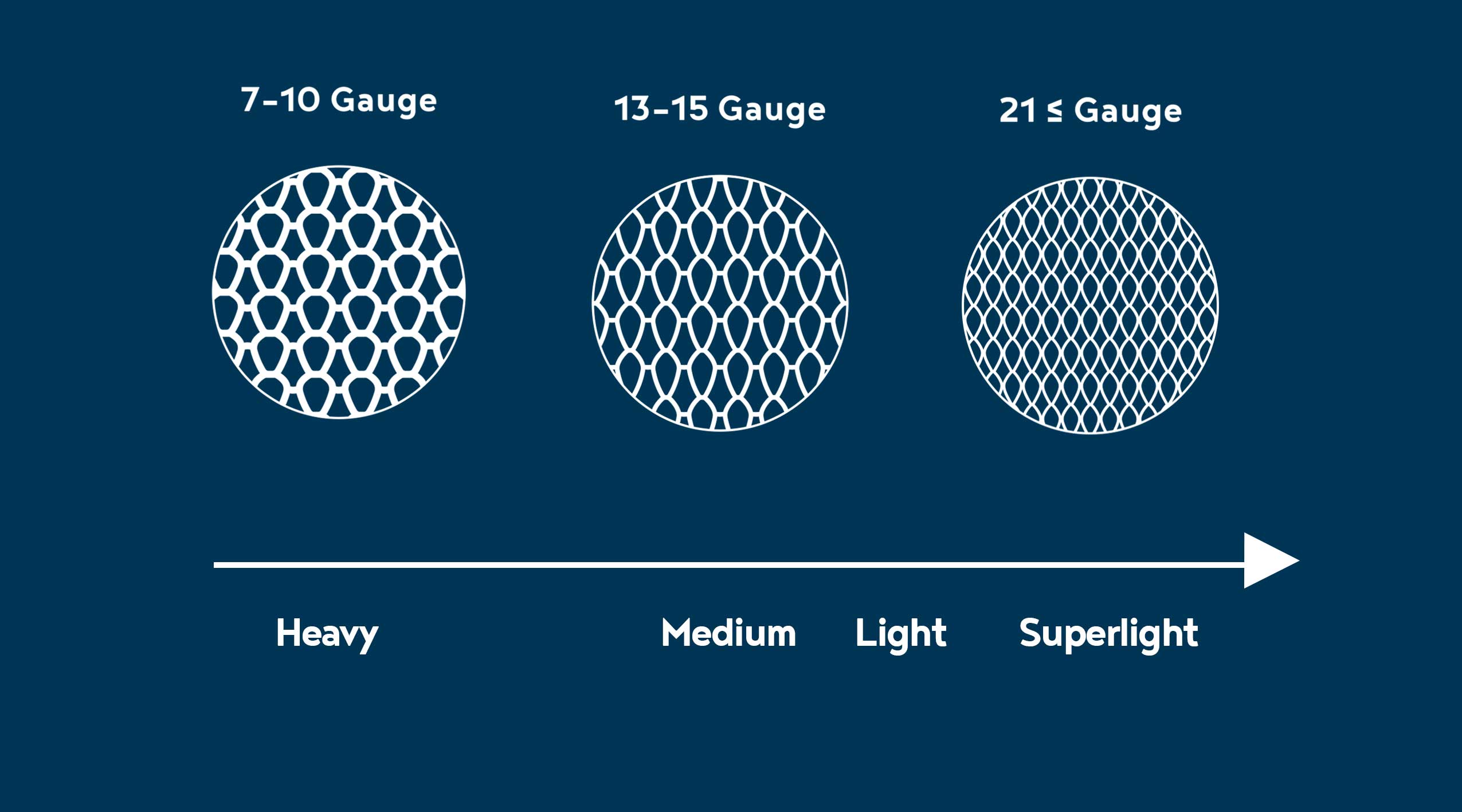

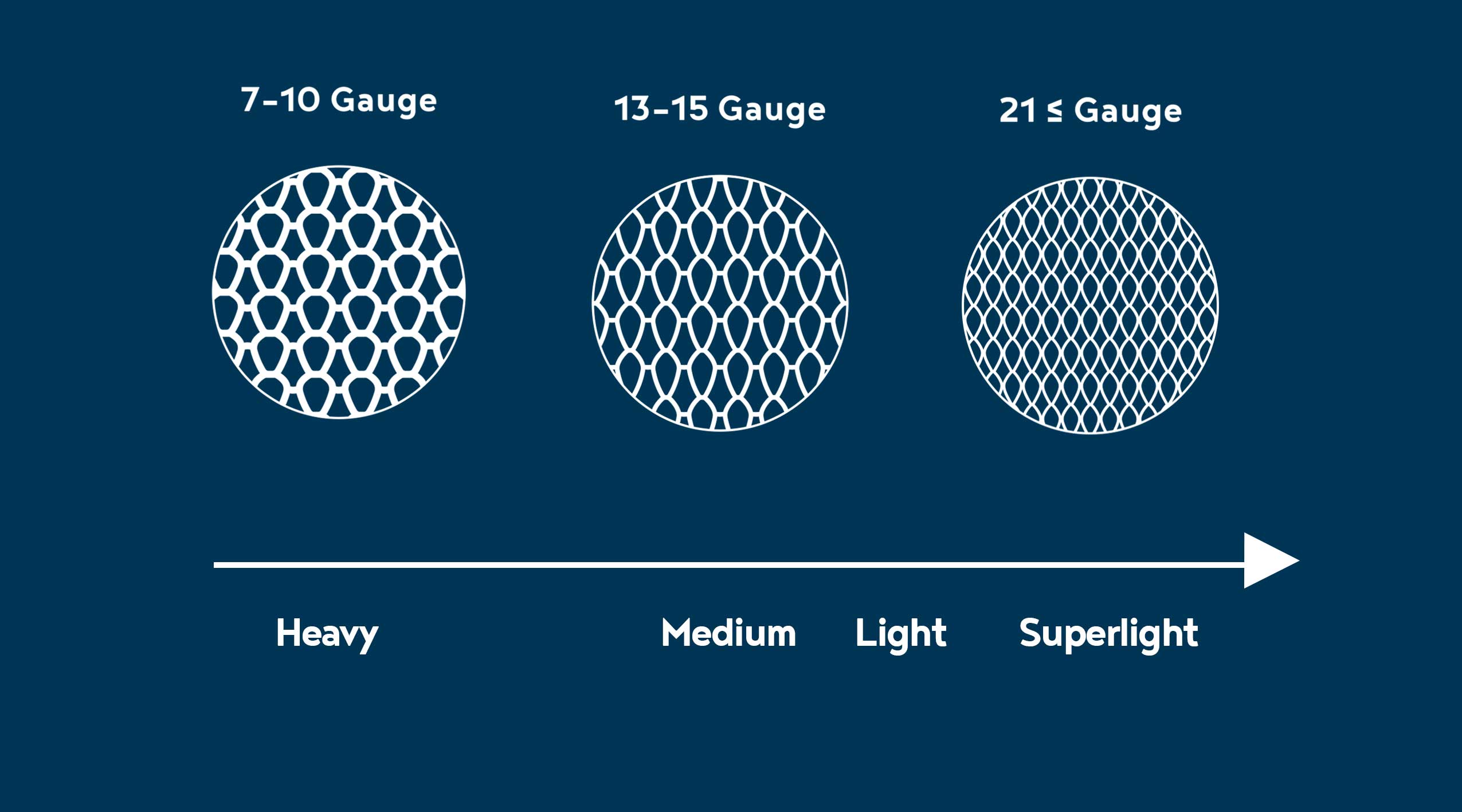

Assembly Gloves

The gauge (GG) indicates the number of stitches per inch in the glove, which affects its thickness and tactile sensitivity. 7-gauge gloves are robust and suited for heavy-duty work, while 21-gauge gloves provide high precision.

Applications: Suitable for all types of assembly work, construction and civil engineering, the automotive industry, process industry, transport, driving, maintenance, and various general uses. This glove category can be used by many professions — for example, craftsmen, warehouse workers, store employees, assemblers, and mechanics.

Example of an assembly glove

Assembly gloves come in many varieties: fully dipped, half dipped, pre-shaped, with impact protection, and with cut resistance.

Our Sanitized® close-fitting work gloves

Several of Wenaas’ close-fitting work gloves are Sanitized® treated. This means they are permanently treated to maintain the gloves’ safety and hygiene by eliminating or reducing the presence and growth of bacteria.

Impact Gloves

Impact-protective gloves are designed to protect the hands from crush and impact injuries, particularly to the knuckles and back of the hand, caused by heavy objects.

Impact-protective gloves are made from both textile and leather materials. The gloves may include additional features such as cut, chemical, heat, or cold protection, allowing them to withstand combined workplace risks.

These gloves are particularly well-suited for construction, offshore work, shipping, and heavy industry, where the risk of crushing injuries and the need for robustness are key factors.

Example of impact glove.

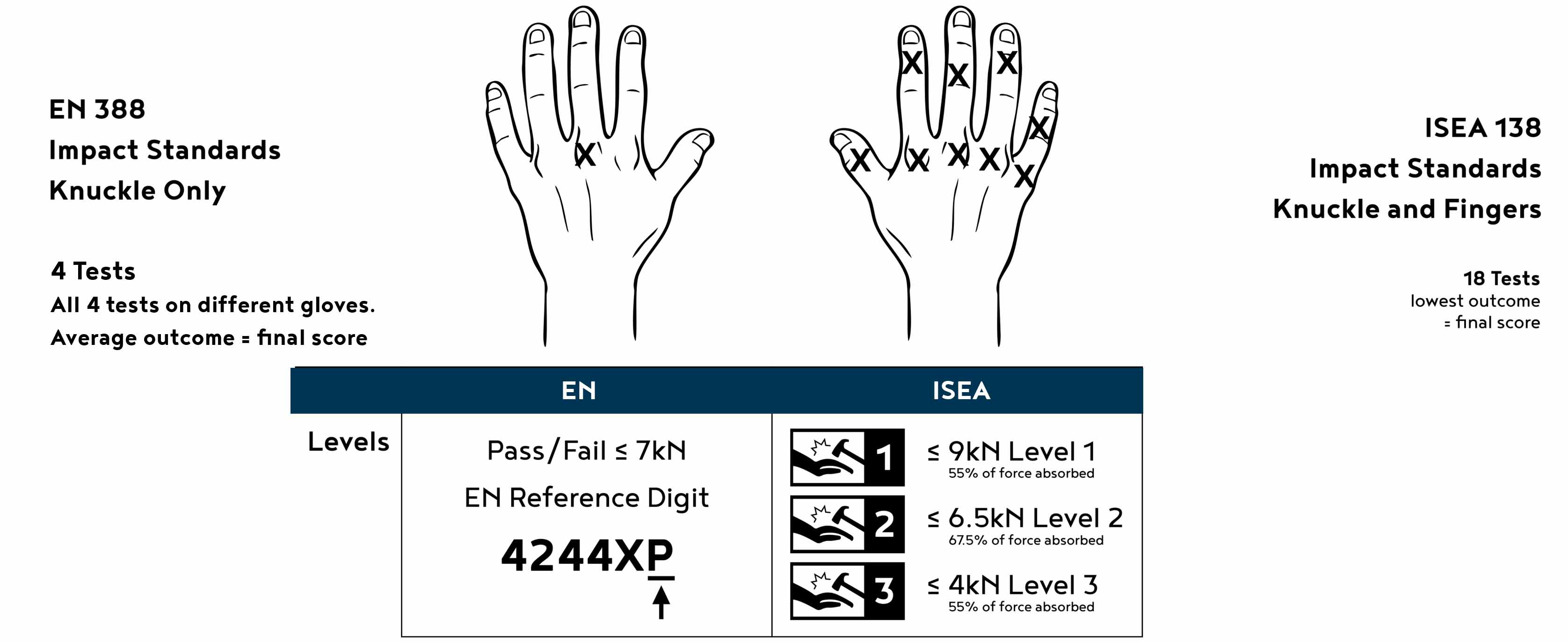

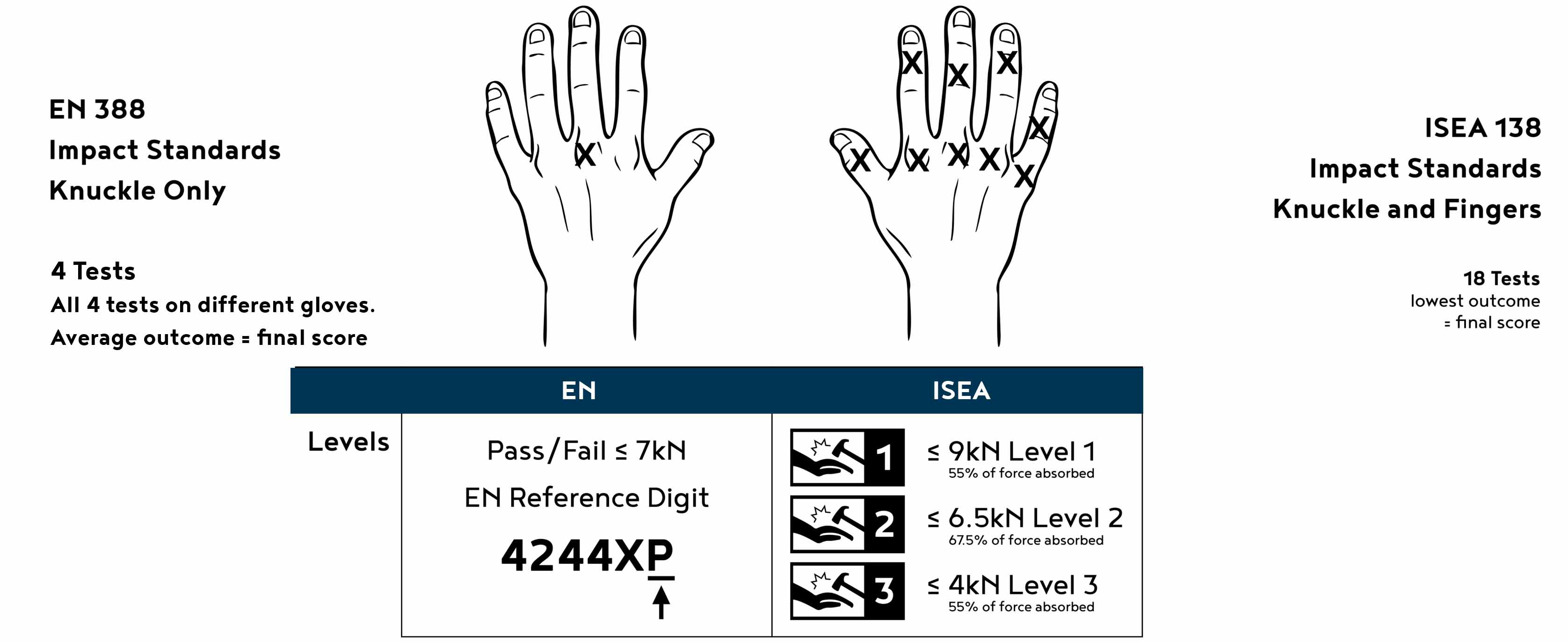

IMPACT TEST

EN STANDARDS = PASS / FAIL

ANSI ISA = SCALE OF APPROVAL LEVELS

Work Glove Wenaas 400

Work Glove Wenaas 410

Cut Resistant Gloves

Work gloves with a close fit, high durability, and cut protection — preferably made from a knitted material containing fiberglass.

- Close fit and high durability

- Cut protection

- Suitable for all types of assembly work and various industrial applications

- All-round category suitable for many uses

Ideal for industries with high requirements for durability and cut protection, such as technical trades, electricians, and assembly work, among others.

Example of cut resistant glove.

Cut resistant glove with impact.

Work Glove Wenaas 200

Work Glove Wenaas 225

Work Glove Wenaas 299

TENCEL™ LYOCELL by Lenzing AGOne of the best sustainable alternatives to cotton is TENCEL™ Lyocell. TENCEL™ Lyocell fibers are derived from wood, a raw material sourced from controlled and certified forests. These cellulose fibers are of botanical origin and are produced in a unique closed-loop process that minimizes environmental impact — a process that recycles water and 99.8% of the solvent used in production. The water consumption for producing TENCEL™ Lyocell fibers is 46 L/kg, compared to 994 L/kg for conventional cotton production.

The fibers have high technical performance, efficiently absorb moisture, and are gentle and soft against the skin. Not only do they absorb 50% more moisture than cotton fibers, but the moisture also evaporates faster, helping you feel cooler and drier. Garments made with TENCEL™ Lyocell fibers retain their color even after many industrial washes — a major advantage for maintaining long-lasting color vibrancy.

That’s why we believe TENCEL™ branded fibers perfectly align with our sustainability standards while also enhancing the protective and comfort qualities of our products.

TENCEL™ Lyocell Glove

Work gloves with arc flash protection

Work gloves with arc flash protection can withstand the extreme temperatures and pressure associated with electrical voltage.

- Arc flash protection

- Withstands extreme temperature and pressure

- Specially designed for high-voltage and electrical work

The gloves are particularly suitable for electricians, line workers, and others working with high-voltage installations, transformers, and electrical systems.

Kutthanske med lysbuebeskyttelse.e with arc protection.

Categories help ensure the correct level of protection against arc flash exposure.

Arc flash protection is measured by the material’s ability to resist heat transfer from an arc flash, expressed as ATPV (cal/cm²). ATPV indicates the energy level that penetrates the material — the higher the ATPV value, the better the protection.

Arc flash categories (1–4) define minimum protection levels based on the NFPA 70E standard (safety in electrical work).

The categories within arc flash protection refer to the levels of protection required in work situations with a high risk of arc flashes. These categories are defined according to the NFPA 70E standard, which is an American standard for electrical safety in the workplace. Each category requires a minimum level of arc flash protection, measured in calories per square centimeter (cal/cm²), to reduce the risk of burns.

The test method determines the glove’s level of protection against electric arc by measuring the amount of heat energy transferred through the tested gloves during and after exposure to an electric arc. The arc thermal performance value (ATPV, cal/cm²) represents the amount of energy that penetrates the glove/material, resulting in a 50% probability of sufficient heat transfer through the glove to cause the onset of a second-degree burn. The higher the ATPV value achieved in testing, the greater the level of protection the glove provides against arc exposure.

Gloves with arc flash protection can significantly reduce injuries in the event of exposure to an electric arc, but they do not eliminate the risk entirely. The level of protection may be reduced if the gloves come into contact with substances such as gasoline, diesel, oil, sweat, dirt, grease, or other contaminants.Before use, the wearer is responsible for implementing appropriate safety, health, and environmental measures, and for complying with all relevant workplace regulations. The standard currently does not have a pictogram, but the ATPV level is indicated on the glove label.

Category 1

1. Low risk.

2. Protection against energy levels up to 4 cal/cm².

3. Basic arc-rated clothing and gloves, such as a long-sleeved shirt and trousers.

Category 2

1. Moderate risk.

2. Protection against energy levels up to 8 cal/cm².

3. More durable arc-rated protective equipment, including stronger gloves.

Category 3

1. High risk.

2. Protection against energy levels up to 25 cal/cm².

3. Requires heavy-duty arc-rated clothing and fully protective gloves.

Category 4

1. Extreme risk.

2. Protection against energy levels up to 40 cal/cm².

3. Full body protection, including a hood, face shield, and heat-resistant gloves.

Winter Gloves

Wenaas 300-collection

Ideal for use in construction, transport, warehousing, assembly, fisheries, shipping, forestry, and shipyard industries — essentially any job that requires a warmer type of work glove.

Winter Glove Wenaas 300

General Work Gloves

Wenaas 700-collection

Welding and Heat-Resistant Gloves

Wenaas 500-collection

Uniform Gloves

Wenaas 800-collection

Suitable for police, ambulance personnel, firefighters, drivers, and all professions where the gloves are designed to match the uniform.

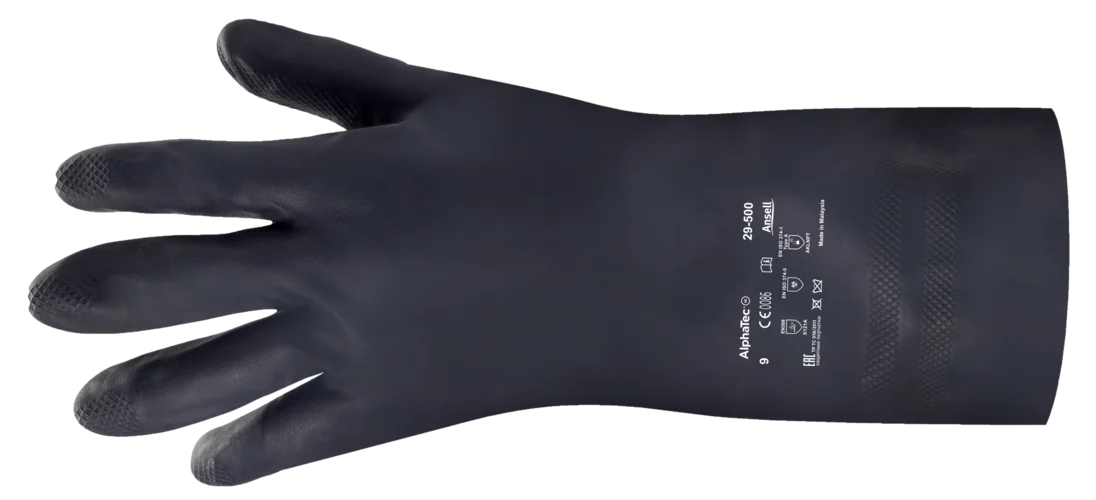

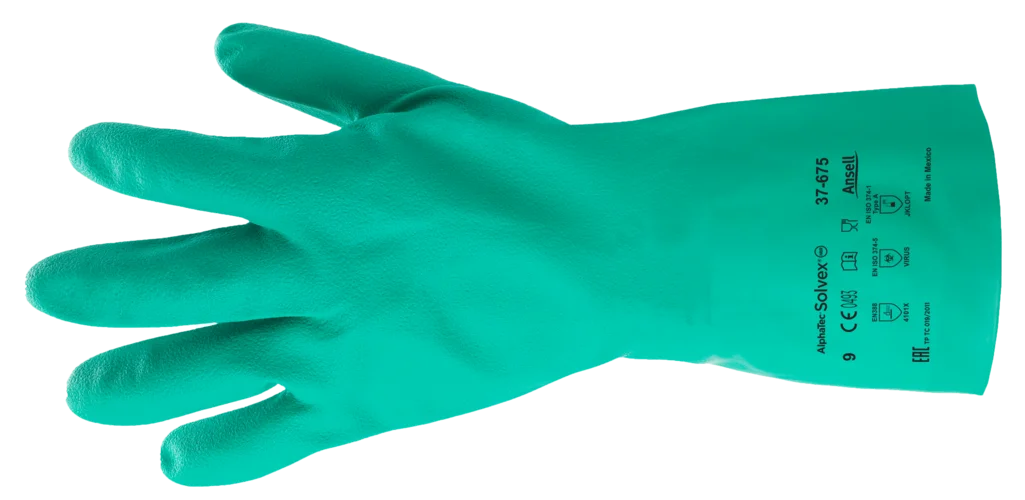

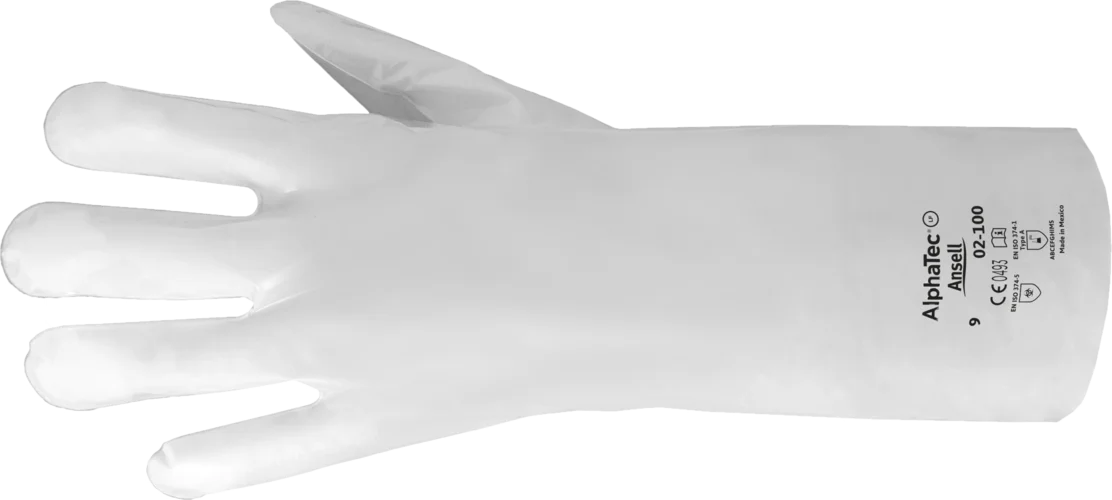

Chemical-Resistant Gloves

Suitable for all industries where workers handle hazardous materials, chemicals, lubricants, food products, or require maximum protection.

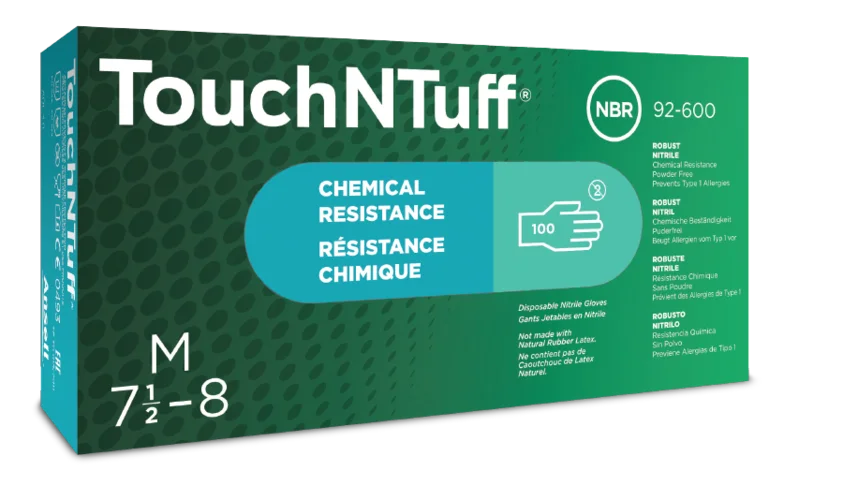

Disposable Gloves

Suitable for professions involving inspection, parts handling, repair, maintenance, oil and gas, transport, food industry, healthcare, assembly, and repair work. Many disposable gloves also offer protection against hazardous substances and chemicals.

Textile Glove

Ideal as inner gloves for “all” industries and applications, but are often used under chemical protective gloves.

Natural warmth and comfort with merino wool!

Winter gloves made from merino wool provide natural warmth and breathability while keeping your hands dry – from lightweight liner gloves to durable models with cut protection. Comfort and protection, no matter the task.

Merino wool is at the core of our three new winter gloves – whether you need a thin and flexible liner glove, a precise assembly glove, or a robust glove with advanced cut resistance and ESD protection.

Work gloves with special protection

Suitable for specialized industries such as firefighting, industrial emergency response, offshore work, and occupations exposed to electrical hazards.

Accessories – gloves

Certifications that underline our commitment to quality, health, and the environment

Through recognized approvals and certifications, we demonstrate that we take responsibility – not only for the products we deliver, but also for the people who use them and the environment we all share. The certifications document our dedicated work toward sustainable solutions and a strong focus on safety at every stage.

The certification is a strong recognition of our commitment to quality, safety, and health. You can be confident that our gloves are made without harmful chemicals.

OEKO-TEX® STANDARD 100 - for textiles

OEKO-TEX® Standard 100 is an international certification for textiles that guarantees the product has been tested for harmful substances and is safe to use. In short:It applies to all textile-related products – from raw materials to finished goods.

The products are tested for more than 100 different substances that may be harmful to health, including heavy metals, formaldehyde, and pesticides. The closer the product is intended to be in contact with the skin, the stricter the requirements. This provides assurance for both consumers and manufacturers that the textiles are safe for health and produced responsibly.

Sanitized® Gloves

Several of Wenaas’ close-fitting work gloves are Sanitized® treated. This means they are permanently treated to maintain the gloves’ safety and hygiene by eliminating or reducing the presence and growth of bacteria.

CE categories

Protective gloves that meet safety requirements are given a CE mark. Protective gloves are divided into three categories.

Categories 1 – Minimal risks

Protects against minor risks. The manufacturer is responsible for ensuring that the product meets the requirements and guarantees the CE marking.

Categories 2 – Intermediate risks

Meets basic requirements as well as additional standards for specific applications. Must be tested in an approved laboratory and type-approved by a notified body that issues a certificate.

Categories 3 – Serious risks

Includes exclusive protection against risks that can cause very serious consequences, such as death or permanent health damage. The gloves must be tested by an approved laboratory and type-approved by a notified body. In addition, an annual inspection of the production process is required, and the product must be thoroughly checked to ensure consistent quality. The ID code of the authorized body (four digits) follows the CE mark, for example: CE 1234.

EN ISO 21420:2020

The standard covers several aspects to ensure that the gloves provide adequate protection and comfort.

Here is a brief overview of the key points in the standard:

Design and construction: The gloves must be designed so that the user can perform normal activities without restriction.

Innocuousness: The materials used must not be harmful to the user.

Maintenance and cleaning: Instructions for maintenance and cleaning must be clear.

Comfort and efficiency: The gloves must be comfortable to wear and effective for their intended use.

Marking and information: The gloves must be clearly marked with the necessary information.

Sizing and measurement: The size of the gloves must be determined according to a defined hand measurement system.

General requirements and test methods

The gloves must be made to provide the protection they are intended for.

The material, seams, and edges must not cause injury to the user.

The gloves must be easy to put on and take off.

The pH value of the gloves must be between 3.5 and 9.5.

The chromium (VI) content must be below 3 mg/kg in leather gloves.

DMFa (dimethylformamide) in gloves containing PU must be below 1000 mg/kg.

The manufacturer must provide a list of known allergens upon request.

The protective quality of the gloves must not be affected if the washing instructions are followed.

The gloves must allow maximum finger mobility (dexterity) according to the required level of protection.

If electrostatic properties are claimed, the gloves must be tested according to EN 16350:2014.

EN ISO 21420 places strong emphasis on innocuousness, ensuring that protective gloves have no harmful effects on the user’s health or hygiene. Each pair comes with a user manual containing relevant information on standards, the manufacturer, maintenance and cleaning, and intended applications. We recommend reading this carefully.

These are the marking requirements for gloves:

Each protective glove must be marked with the following information:

- Manufacturer’s name

- Glove designation

- Size designation

- Pictograms indicating the applicable standards for the glove, including reference and performance levels

- Date of manufacture

- Expiry date (if applicable), shown with an hourglass symbol

If it is not possible to mark the glove itself, the above information must be included on the first

packaging insert.

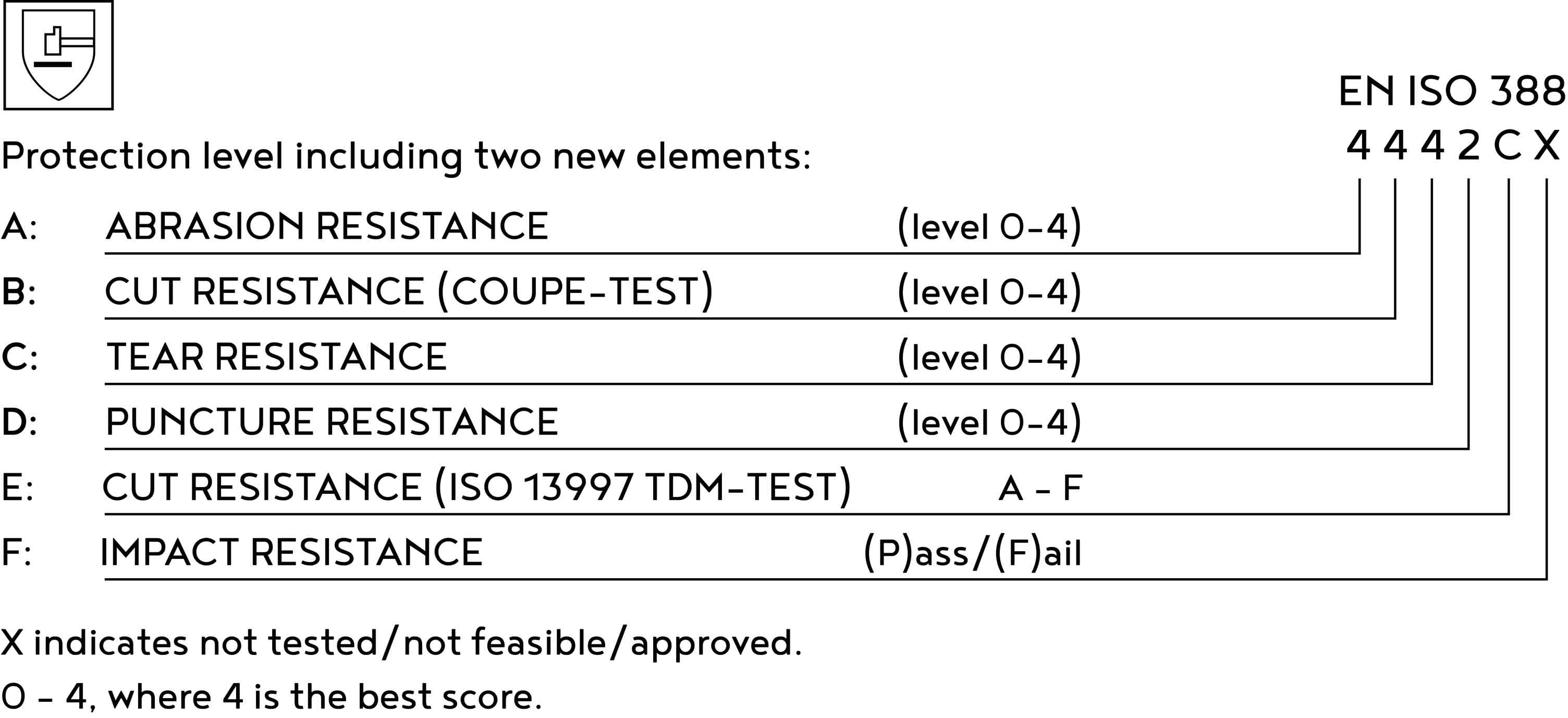

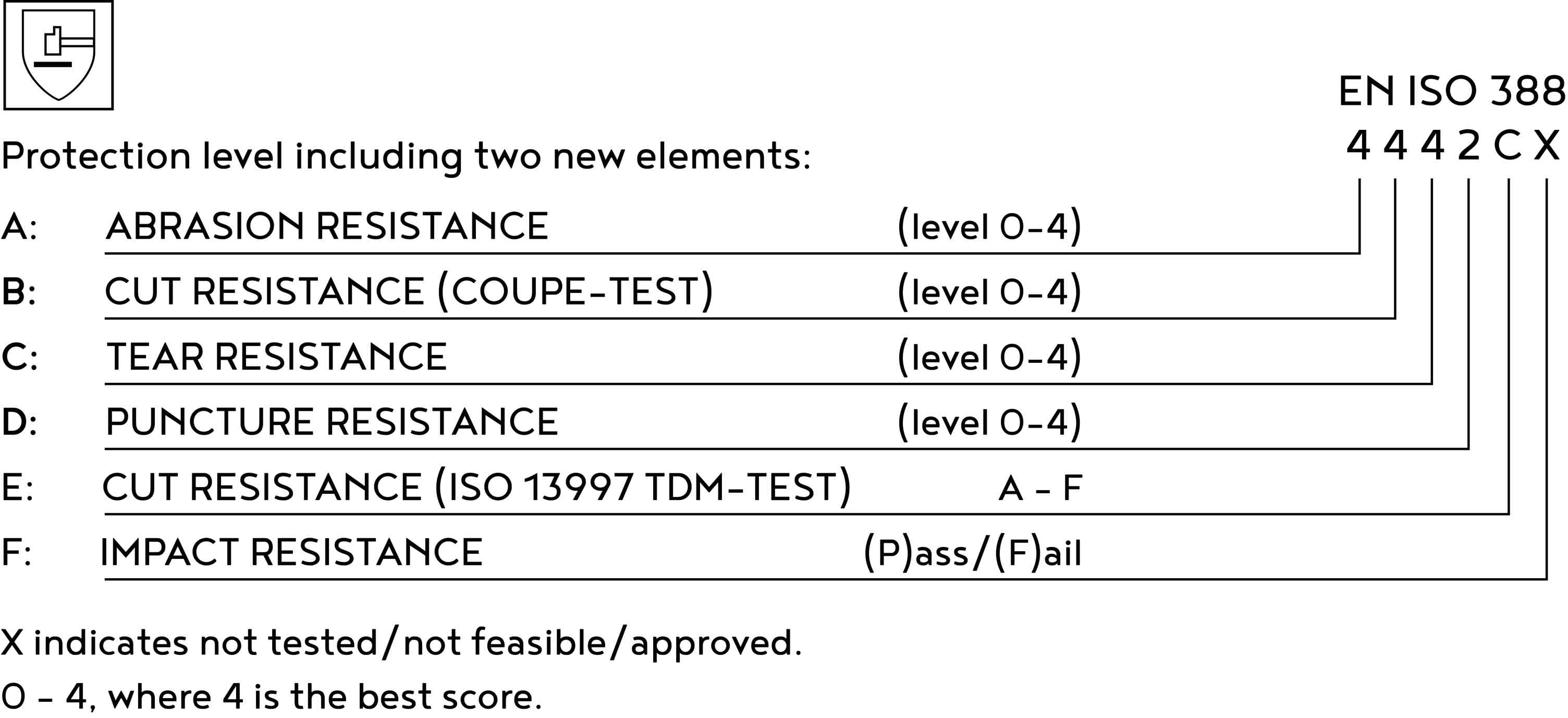

NS-EN 388

Protective gloves against mechanical risks

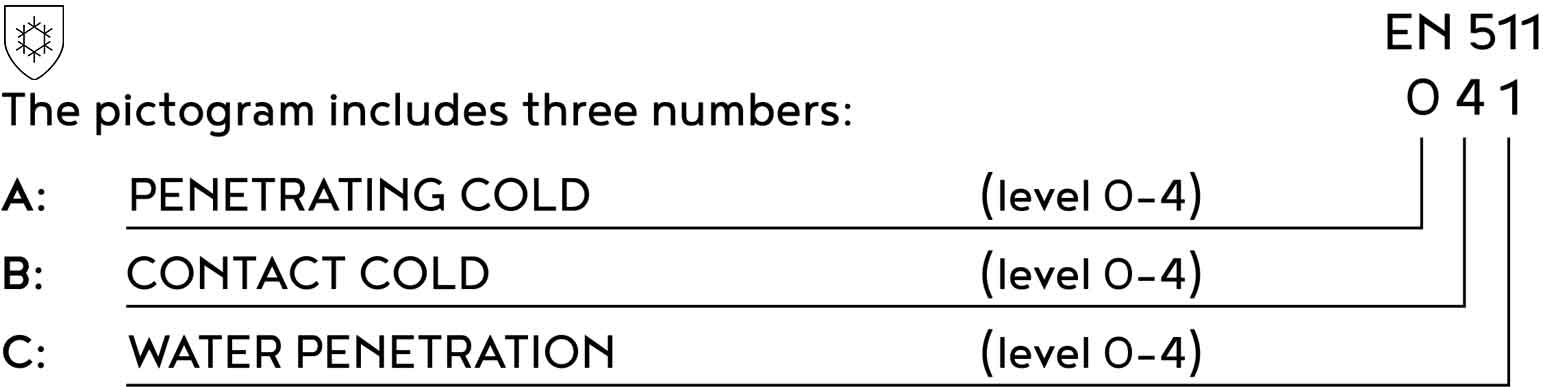

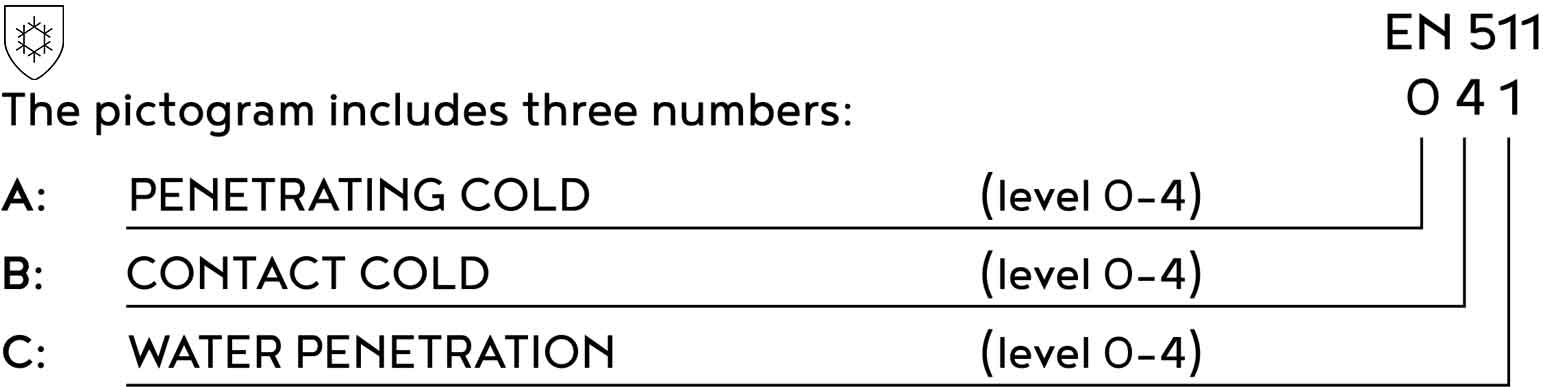

EN 511

Protective glove against cold

This norm is used for gloves designed for working in cold environments, whether due to weather conditions or by exposure to chilled or freeze-controlled materials.

Marking for EN 511

Gloves that have been tested and certified according to EN 511 will have a marking that looks like this: EN 511: xyz, where:

x = Protection against convective cold (0–4)

y = Protection against contact cold (0–4)

z = Resistance to water penetration (0 or 1)

Example: EN 511: 3, 2, 1, this means

•3: Good resistance to convective cold

•2: Moderate resistance to contact cold

•1: Waterproof

Applications

Gloves that comply with EN 511 are typically used in work environments such as:

• Outdoor work in cold climates (construction, transportation, agriculture)

• Work in cold storage and freezer warehouses

• Handling of cold materials in the industrial and logistics sectors.

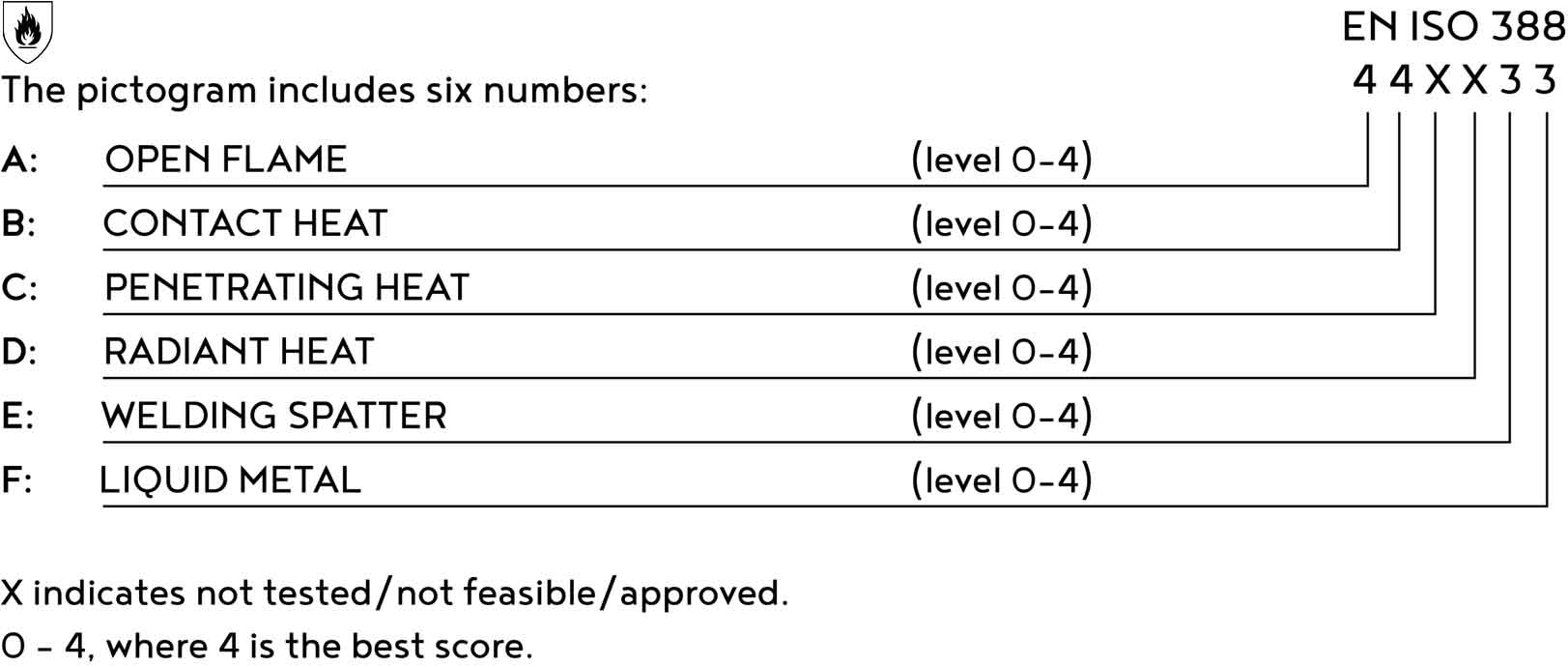

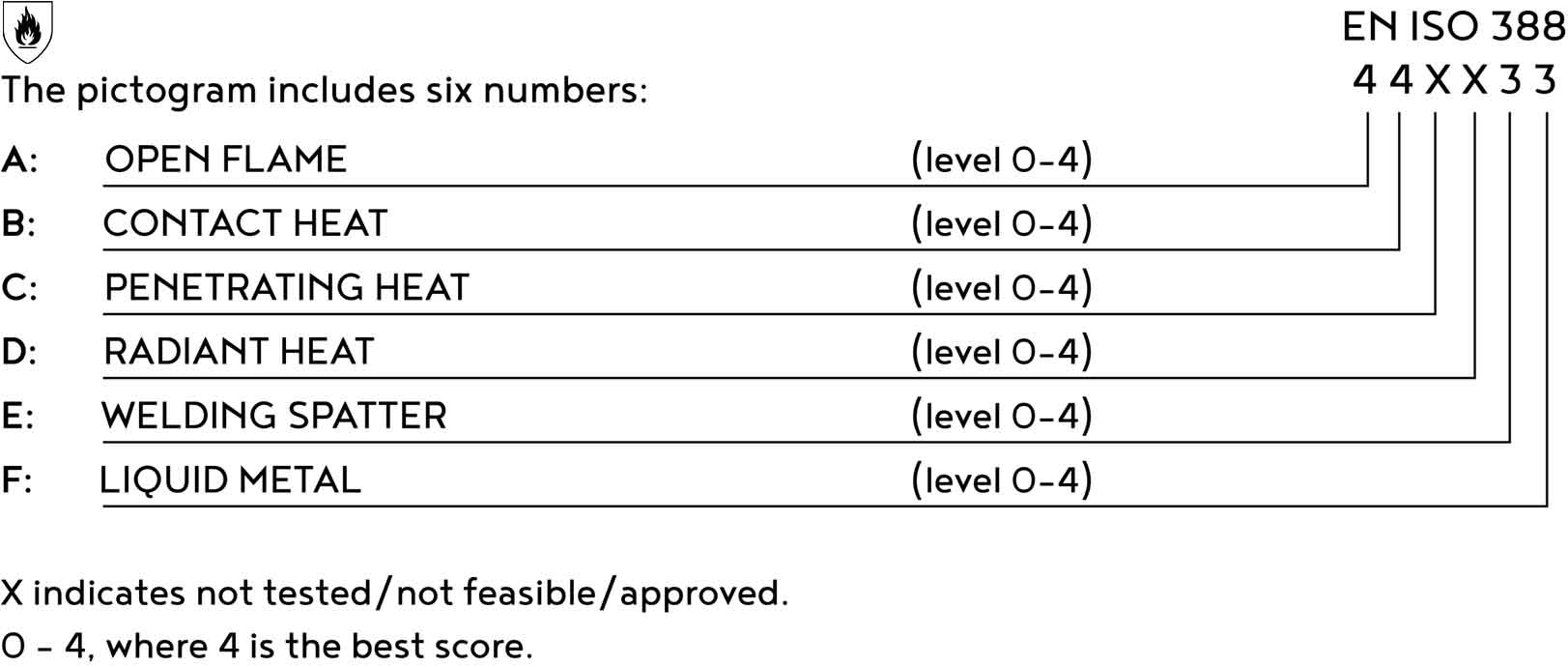

EN 407

Protective gloves and other hand protective equipments against thermal risks (heat and/or fire)

Gloves designed to protect against thermal hazards, including exposure to heat and flames. This standard is applicable to gloves used in work environments with high temperatures or risk of flammability.

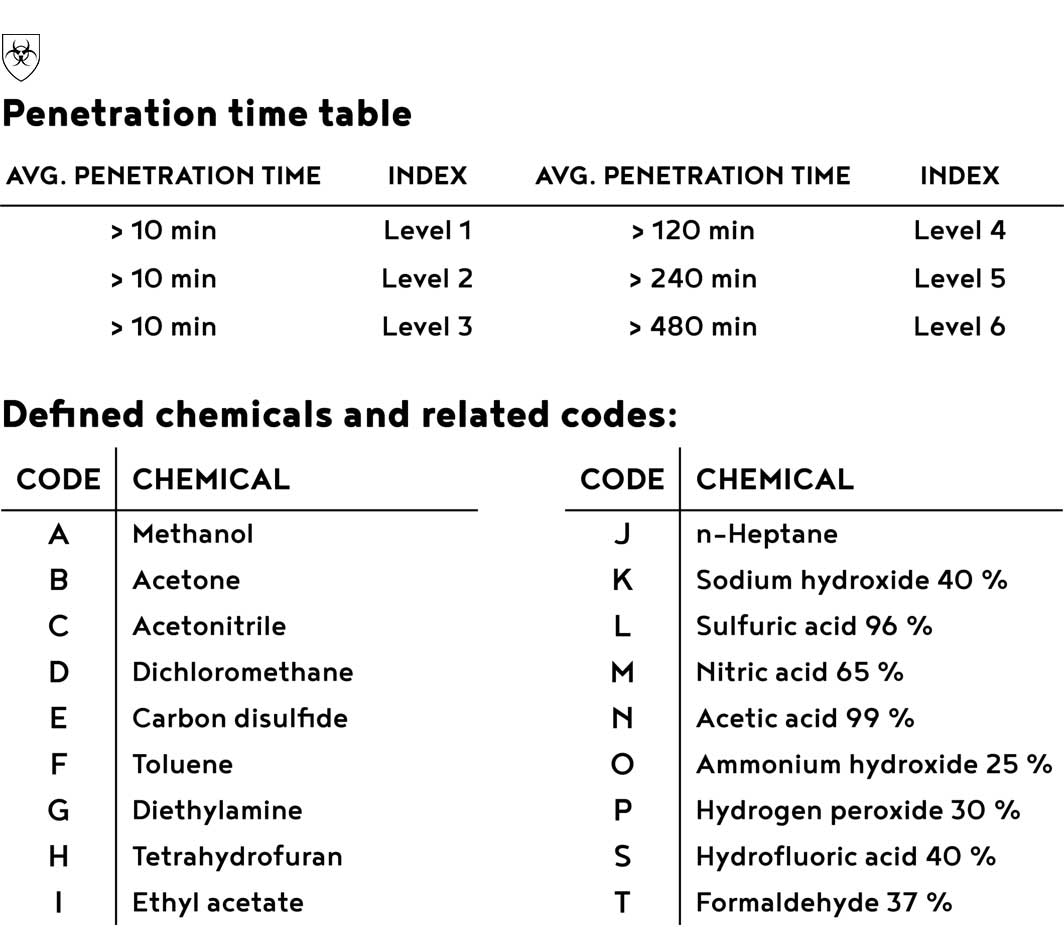

EN 374-1 and EN 374-5

Protective gloves against dangerous chemicals and micro-organisms

Gloves that protect against chemicals, bacteria, viruses, fungi, and more. Such gloves are commonly used in laboratory work, healthcare, and tasks involving chemicals.

EN 374 is a European standard for gloves that protect against chemical and microbiological risks. It is used to certify gloves that provide protection against chemicals, microorganisms (bacteria, viruses, and fungi), and in some cases, hazardous liquids. The standard consists of several parts that cover different types of risks and testing methods.

When are EN 374 gloves used?

Gloves certified according to EN 374 are used in situations where protection against chemicals or microorganisms is required, for example:

- Laboratory workHealthcare (protection against viruses and bacteria)

- Industrial work involving chemicals

- Cleaning tasks using strong agentsIt is important to choose gloves that are suitable for the specific chemicals and hazards present in your work environment.

The chemical resistance table (including breakthrough time and degradation) should always be consulted before use.

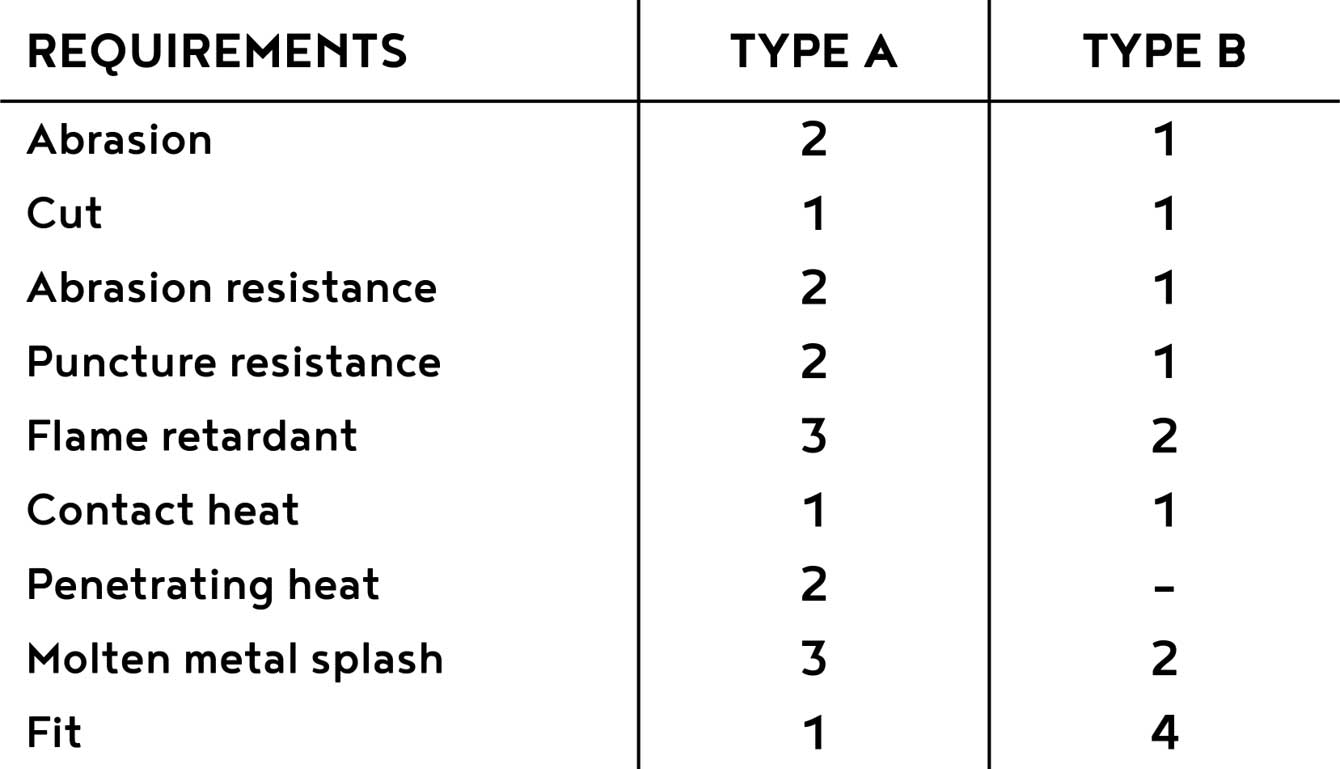

EN 12477

Protective gloves for welders

Welding gloves are specially designed to provide optimal protection against heat, sparks, and welding spatter during welding and other high-temperature work. They are typically made from durable leather, such as cowhide or goatskin, and often feature heat-resistant linings for added safety and comfort. Longer cuffs protect the forearms, and the seams are usually stitched with heat-resistant thread to withstand extreme temperatures. Whether for MIG, TIG, or arc welding, there are gloves designed to meet every specific need.

EN 659

Protective gloves fpr firefighters

EN 60903

Gloves of insulationg material

EN 10819

Mechanical vibration and shock — Hand-arm vibration — Measurement and evaluation of the vibration transmissibility of gloves at the palm of the hand

EN 1149-3

Protective clothing — Electrostatic properties

EN 421

Protective gloves against ionizing radiation and radioactive contamination

SPECIAL GLOVES FOR FIREFIGHTERS

These gloves are designed to provide protection against heat, flames, cuts, punctures, and other hazards that firefighters may encounter during rescue operations and firefighting. In addition, the gloves must be flexible enough to allow the user to handle equipment effectively.

INSULATING GLOVES FOR ELECTRICAL WORK

These gloves are tested and approved to withstand electric shock, which is crucial for safety in high-voltage work environments. They are also tested for mechanical stress, aging-related degradation, and resistance to other factors such as flame, temperature, oil, and more.

PROTECTION AGAINST MECHANICAL VIBRATIONS AND IMPACT

The standard defines requirements and testing methods for gloves designed to reduce vibrations from handheld tools such as drills, angle grinders, and chainsaws. The gloves must be comfortable enough for normal tool operation while effectively reducing vibrations to minimize health risks.

PROTECTION AGAINST STATIC ELECTRICITY

This standard specifies the properties required to manage electrical charges that may occur in explosive environments. The materials must minimize the risk of electrostatic discharge that could cause sparks and potential explosions, particularly in industrial settings or electronics manufacturing.

PROTECTIVE GLOVES AGAINST IONIZING RADIATION AND RADIOACTIVE CONTAMINATION

Products developed to provide protection in environments where there is a risk of ionizing radiation and radioactive contamination. These may include medical, nuclear, or laboratory settings. The materials must have high density—often reinforced with lead—and are tested for permeability under pressure.

Glove thickness (Gauge)

Gauge refers to the glove’s thickness and indicates the number of stitches per inch.

10-gauge: Thick and durable, suitable for heavy-duty work.

13-gauge: Balanced durability and dexterity for general tasks.

15-gauge: Thinner, suitable for handling small parts.

18-gauge: Very dexterous, ideal for precision work.

21-gauge: Extremely thin, excellent for fine tasks.

PU-dipped

- More flexible and elastic feel

- Used where fingertip sensitivity is most important

- PU microfoam is soft and resistant to water and lubricants

- Allows air to pass through, keeping hands dry

- Provides excellent grip, especially in dry environments

RECOMMENDED: For tasks that require optimal fingertip sensitivity and where the working environment is dry.

Nitrile-dipped

- Nitrile microfoam provides excellent grip in both dry and wet conditions.

- Also offers a strong grip in oily environments.

- Can be double-dipped to make the glove liquid- and oil-resistant.

- Withstands high temperatures.

- Highly durable with excellent tear resistance.

- Protects against bases, acids, solvents, lubricants, and animal fats.

RECOMMENDED: For those working in oily environments such as workshops, the automotive industry, or other mechanical industries.

The table shows the propperties of nitrile and PU coating.